Automatic doors have sensors, controllers, motors and drive mechanisms. They are the one of the most common robotic systems people encounter. Please see this page for more information on how

automatic doors work. A

peer-reviewed

paper I authored discusses automatic doors and their safety systems in the context of “collaborative robotics.” Collaborative robotics describes applications where robotic

systems and humans interact and share the same space, such as

automatic pedestrian doors.

If you are reading this page, you may be looking for an automatic door expert witness to help you with a case involving an

automatic door accident.

I have been a testifying expert

in dozens of cases across the country. I also have a PhD in

engineering, am a Registered Professional Engineer, and my

peer-reviewed publications appear in books, journals and

conference proceedings. Please contact me to discuss your case

and continue reading for a brief overview of the ANSI automatic door standard,

example engineering analyses of automatic doors, and some history of automatic door control

systems.

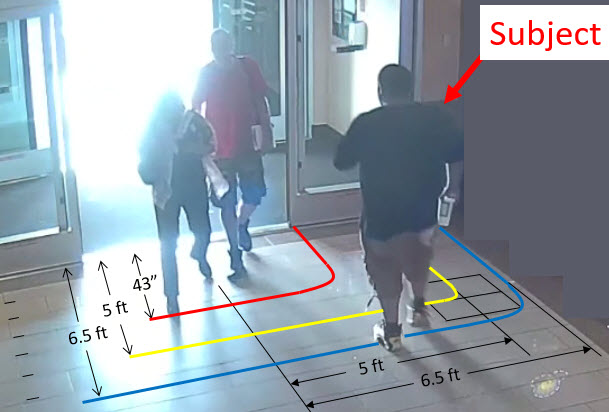

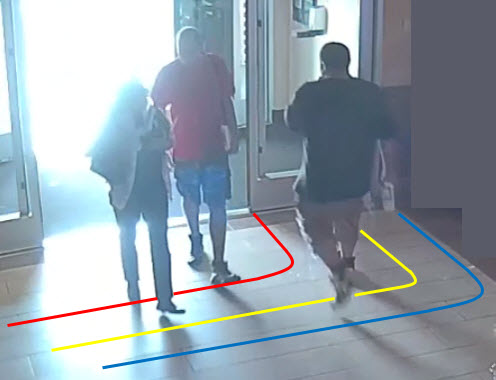

When there is an injury involving an automatic door, there is often video evidence recorded from the scene. This video, when combined with physical measurements taken during an inspection, allows us to superimpose the activation and safety zones onto the scene of the accident. Then we can follow the people and the door as they move within the scene.

The figures below show activation and safety zones superimposed on video from a camera pointed towards an automatic door during the brief time period immediately before a collision. The activation zone refers to the area generally in front of the door where an approaching person will cause the door to open. The safety, or "presence," zone refers to the area in, and immediately adjacent to, the door's path where the presence of a stationary person will cause the door to stay

open. The zones are outlined in red, yellow and blue. The subject person is approaching the automatic door from the inside of the building towards the outside.

|

|

|

| Activation and safety zones superimposed on floor |

Subject proceeds towards automatic door |

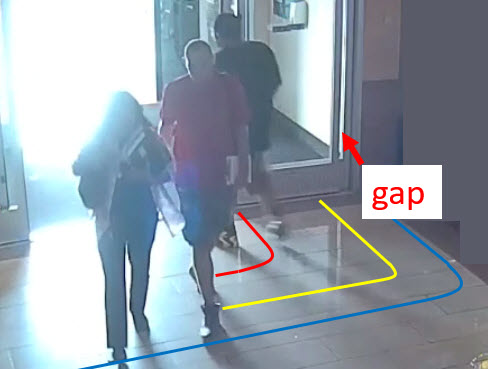

The changes in the scene from frame to frame can be analyzed to determine directions, speeds, accelerations and changes in momentum. For example, the gap in the figure below shows the automatic door is closing even though the subject has stepped into the minimum activating zone, directly towards the sensor mounted above the door. The door should not have been closing under these circumstances.

|

|

| Subject steps into minimum activation zone |

Gap shows the automatic door has started closing |

The ANSI/BHMA A156.10 American National Standard applies to power operated pedestrian doors. The standard was first published in 1984 and there have been five updates since, with the most recent being in 2017. The standard calls out many parameters including the maximum forces and speeds for moving doors. It also calls out safety and activation zones for automatic doors.

In addition to engineering factors such as kinematics and dynamics; there are operational and maintenance procedures for automatic doors. For example, all automatic door systems I am aware of specify a daily safety check. This check is called-out in the owner's manual for the door. A business with an automatic door should read and follow the owner's manual(s) for their

door(s).

Automatic doors can be dangerous. They have motors, gears and drive mechanisms that can generate substantial forces. The moving door itself has momentum that will contribute energy to an impact. Furthermore, a door that moves unexpectedly into a person's path and then stops can cause an accident involving considerable forces, even though the door is not moving at the time of the impact.

Door accidents can happen after a person walks through a "blind spot" in the door's sensor system. Some door systems have sensors with known blind spots at the outer edges of the doorway. These systems rely on traffic control to prevent people from walking through the blind spots. The owner's manual for the door should explain whether traffic control is

required.

The first case where I served as an automatic door expert witness was in 2010 in Corpus Christi, Texas when a person was badly injured after a fall caused by a closing automatic door. The technical details of this case focused on the condition and maintenance of the door, and particularly the presence sensor designed to hold the door open so that it would not close on the pedestrian. I testified in front of a jury for the Plaintiff in this case, which resulted in a Plaintiff's verdict for $6.4

million.

In another pedestrian door case where I served as an expert witness, it seemed the performance of the door changed from one inspection to another, even though the door maintenance company had not been on site and the settings of the door had not been changed during either inspection. Eventually we discovered a general maintenance person at the hotel was adjusting the door because he didn't like it to stay open too long when it was hot outside. Only someone with the proper training should be adjusting automatic doors that are used by pedestrians.

Early automatic door systems employed control mats on the floor to control the doors. The control mats were connected to electrical relays that opened the doors when there was weight on the mat and closed the doors when there was no weight on the mat. Two general downsides to this design were that the control mats would wear out from the foot traffic and the mats themselves could become a tripping

hazard.

Later, automatic door systems added computing elements for control and replaced the mats with non-contact sensors, typically mounted above the doors, to detect approaching people. The non-contact sensors eliminated the mechanical problems with the control mats, but introduced other problems, such as sensor blind spots.

For example, one of the sensor types that found wide deployment was a motion sensor based on the Doppler frequency shift. This type of motion sensor identifies the approach of people towards the doors. The computing element then commands the doors to open for the people to move through the doorway. Unfortunately, there were injuries when some people moved so slowly through the doorway that they effectively became invisible to the motion sensing. This danger is exacerbated when the person is directly under the sensor because there will be little or no component of that person’s velocity towards or away from the motion sensor.

To address this issue, the designers of automatic door systems added an infrared presence sensor intended to identify the presence, rather than the motion, of people that could get into the path of the moving door. By adding the second sensing element, the system designers were attempting to eliminate blind spots or weak areas in the sensor coverage pattern. This is important because when people get into the blind spots, the door’s safety systems are not able to protect them and injuries can occur. Other causes of accidents can include improper set-up of the doors, component failures and failure to control the entrance and exit areas of the doors.

|